Research Interests

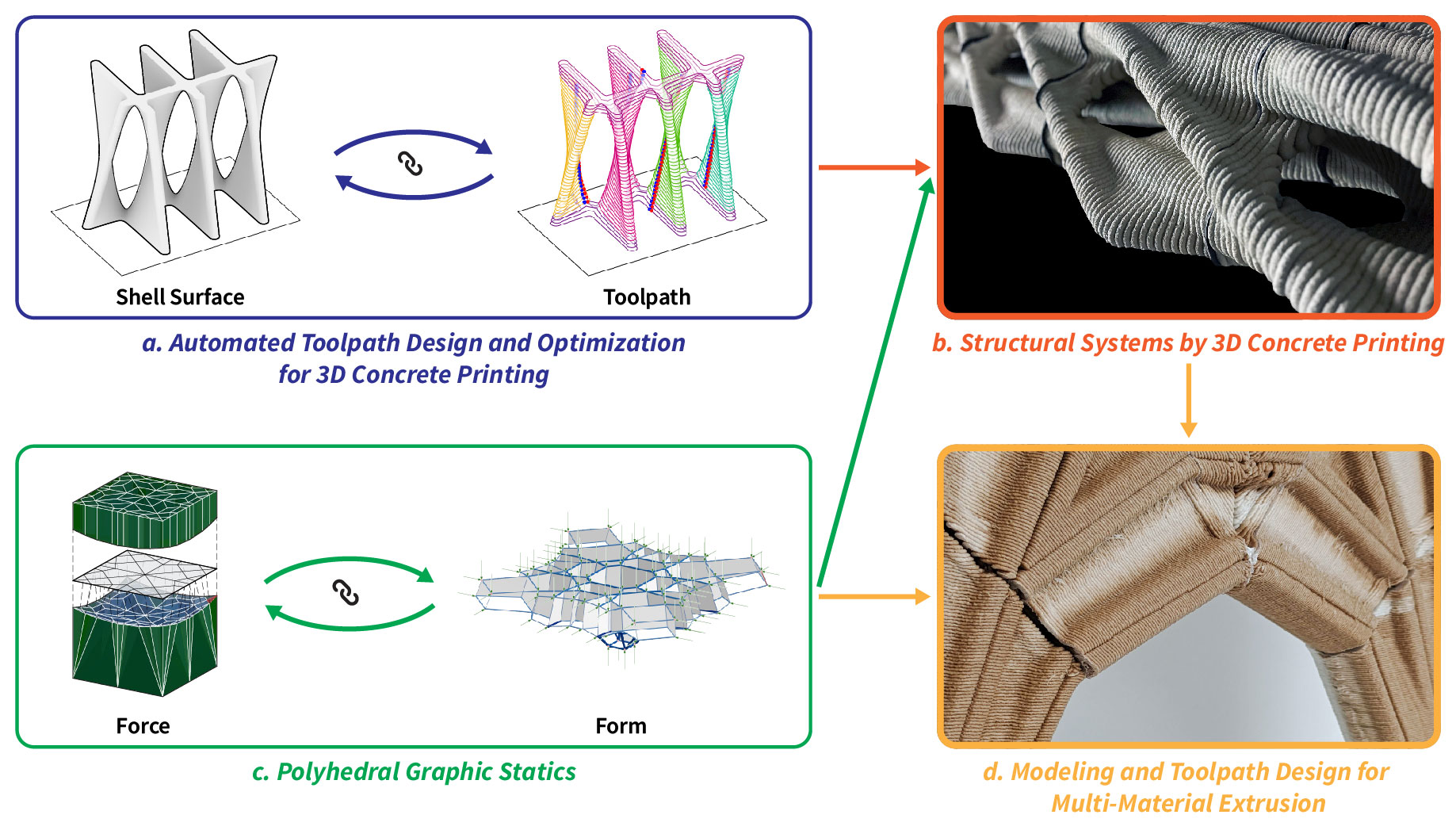

My research interests are outlined in the following diagram. The four components form a road map that guides my collaborators and me in integrating design-for-manufacturing strategies and computational form-finding methods to realize advanced structural systems.a. Automated Toolpath Design and Optimization for 3D Concrete Printing

3D-printed concrete structural components are known for reduced material use, enhanced construction efficiency, and design freedom. Faced with limitations in material properties and extrusion systems, we establish an integrated approach to designing and optimizing the toolpath for a given geometry while maximizing the advantages of 3D concrete printing. We provide methods of predicting and optimizing buildability in terms of local and global overhang, enhancing the dimensional accuracy and surface quality, and generating as-continuous-as-possible toolpaths with minimal stop-starts. By introducing surface-toolpath twins interconvertible through efficient slicing and surface reconstruction algorithms, we build a bidirectional design-to-production process to combine expertise in form-finding and fabrication-oriented design. We also propose using scaled fabrication models 3D-printed the same way as in actual construction to assist design iterations and communication.

Selected Publications / [Short Names] [Full Names]

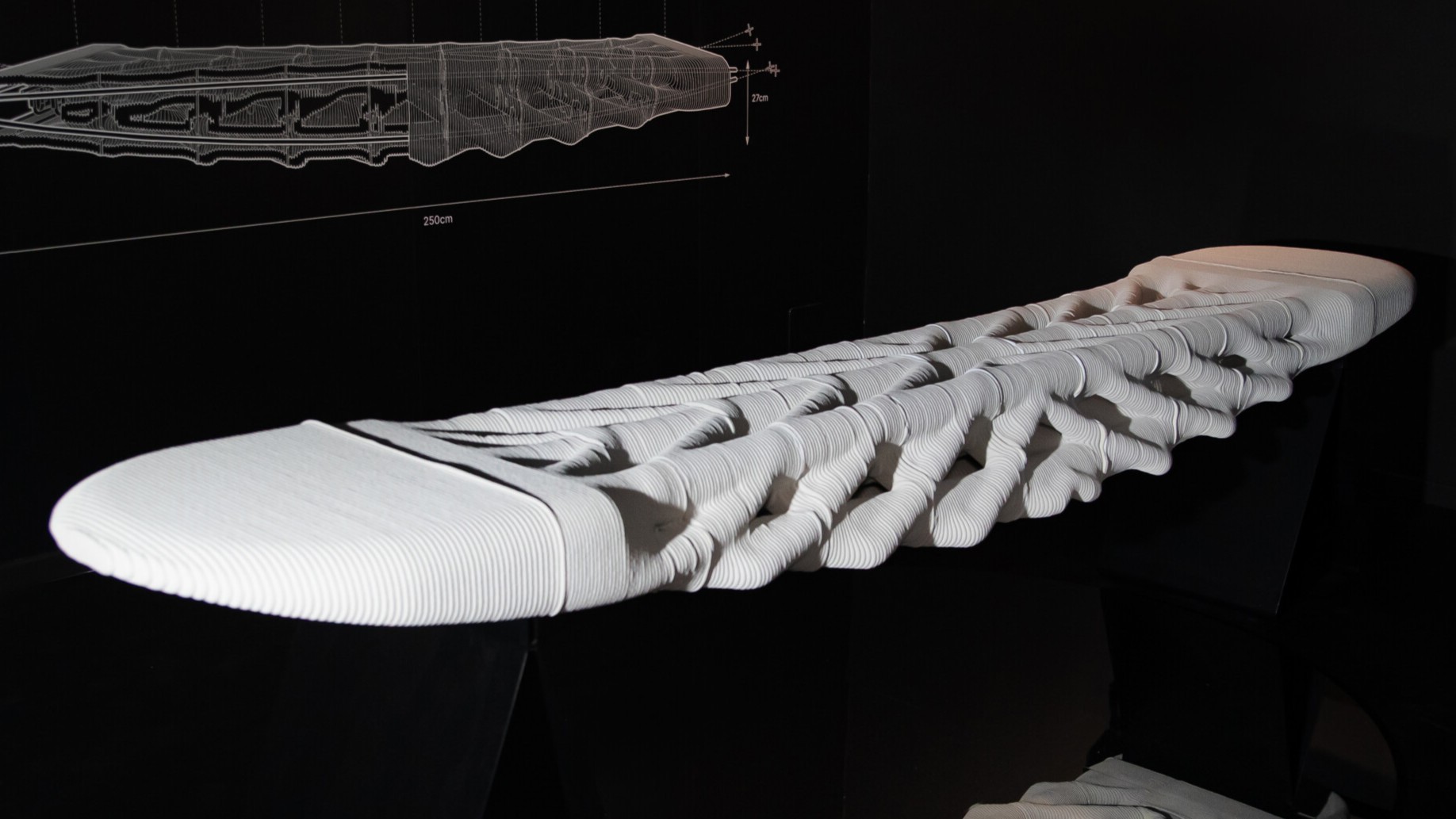

b. Structural Systems by 3D Concrete Printing

The use of 3D concrete printing allowed for the effective realization of innovative structural systems that integrate efficient funicular geometries with tailored functionality. By connecting form-finding results with toolpath design and optimization methods, we have designed and fabricated post-tensioned concrete beam structures at multiple scales, achieving minimal mass and maximized surface area. The prototypes exhibit high geometric fidelity and load-bearing capacity.

Selected Publications / [Short Names] [Full Names]

c. Polyhedral Graphic Statics

The form-finding method of polyhedral graphic statics (PGS) uses reciprocal force and form diagrams to design funicular structures. My research investigates strategies for materializing PGS-based designs across various fabrication platforms and material systems. In addition, I am particularly interested in the data structures and graph algorithms for modeling tension-compression combined forms in PGS.

Selected Publications / [Short Names] [Full Names]

d. Modeling and Toolpath Design for Multi-Material Extrusion

Multi-material extrusion allows complex forms to have locally tailored materials. We propose modeling methods that embed material information in a 3D-printable object referring to sources such as force distribution (e.g. the result of PGS) and local functionalities (e.g. variable insulation or stiffness). Leveraging an integrated gradient multi-material extrusion system and toolpath design methods, we produce multi-material obejcts with high fidelity and minimal waste, contributing to the efficient fabrication of multi-mateiral light-weight, functional structures.

Selected Publications / [Short Names] [Full Names]

Other Design/Construction Projects

Projects not associated with academic publications are listed here.

As Lead Researcher

Dove Wave: Inventory Constrained Design Masoud Akbarzadeh, Yiliang Shao, Yefan Zhi, Sepideh Bayat, Michael Ting Inventory-Constrained Design Competition by Eventscape 2022 New York, NY, US, First Place [Project Page]

As Designer

Diamanti: European Cultural Centre Exhibition Masoud Akbarzadeh, Maximilian E. Ororbia, Amir Motavaselian, Hua Chai, Yefan Zhi, et al. Exhibited at the Venice Architecture Biennial organized by the European Cultural Centre May - Nov 2025 Venice, Italy, ECC Award [Project Page]

As Part of the Installation Team

Glass Bridge: A Clear Path to Sustainability Masoud Akbarzadeh, Joseph Robert Yost, Damon Bolhassani, Jens Schneider, et al. Exhibited at the Corning Museum of Glass Dec 2024 - Sept 2025 Corning, NY, US [Project Page]

Floralis: an ETFE-Cladded, Multilaminar Timber Structure Masoud Akbarzadeh, Dorit Aviv, Frank Mateo, et al. Built in the Florissant Fossil Beds National Monument 2024 Florissant, CO, US [Project Page]

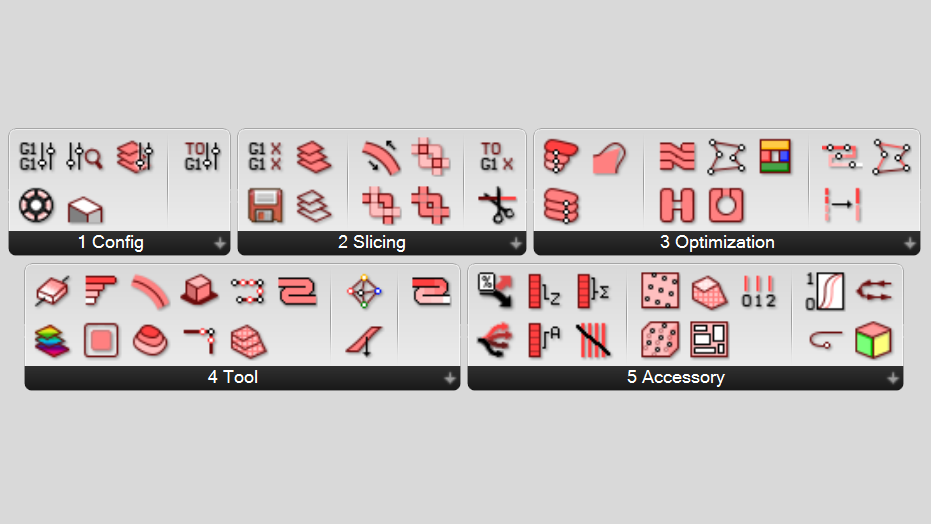

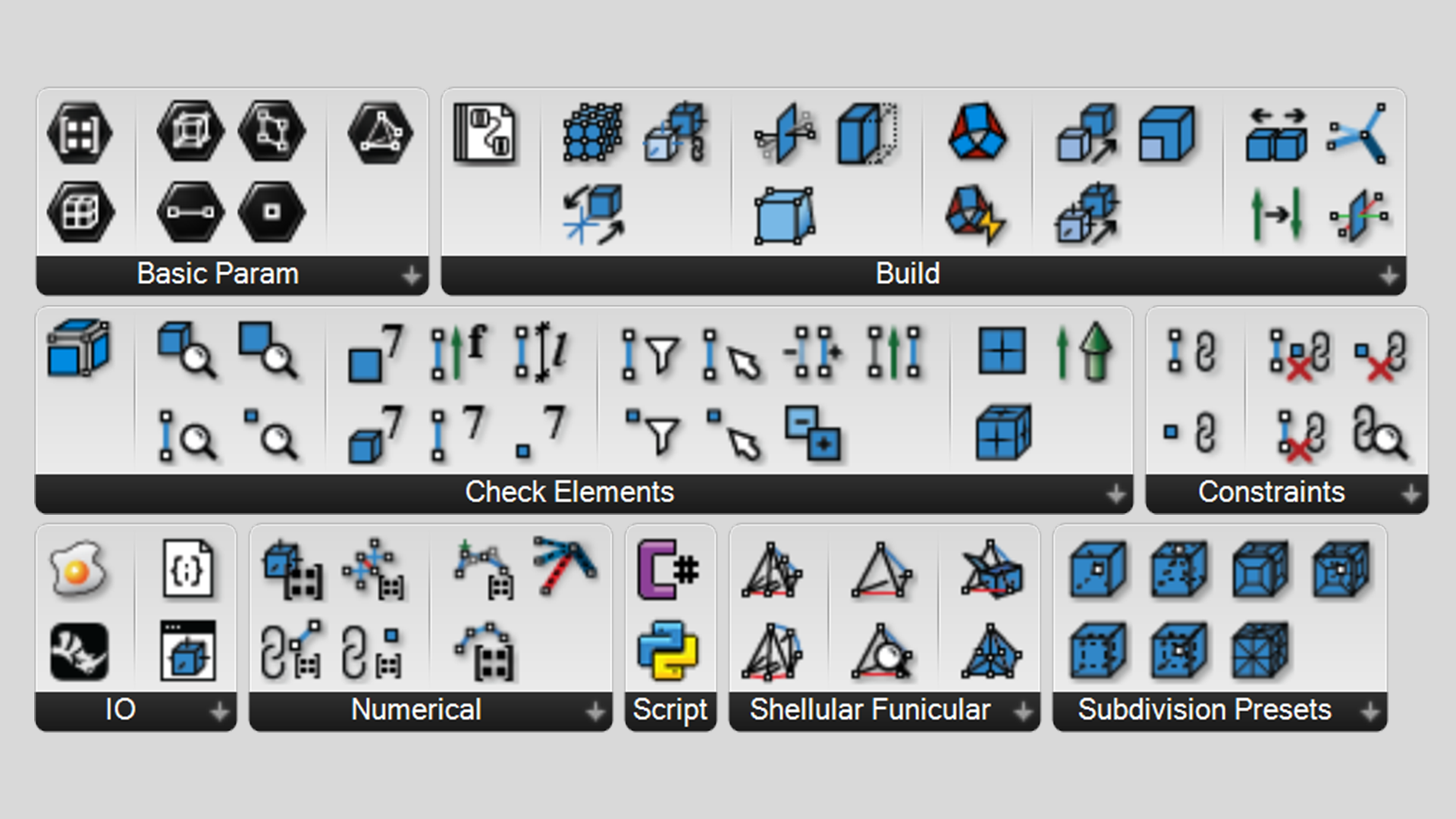

Software Products

Ovenbird: Concrete and Multi-Material 3D Printing Yefan Zhi, Hua Chai, Teng Teng, Masoud Akbarzadeh A plugin for Grasshopper 2022 - 2025 [Code]

PolyFrame 2: Structural Form-Finding with Polyhedral Graphic Statics Yao Lu, Andrei Nejur, Mathias Bernhard, Yefan Zhi, Hua Chai, Mostafa Akbari, Márton Hablicsek, Masoud Akbarzadeh A plugin for Grasshopper 2022 - 2025 [Code]