Surface-toolpath twins

Toolpath Mesh

Toolpath Mesh features a surface reconstruction algorithm that converts a

Toolpath back to a manifold surface in the form of a mesh.

This process is the inversion of

Slice and produces a portable visualization of the printing scheme.

The Toolpath mesh is important

since once a toolpath is modified, the original input geometry no longer reflects truthfully the printing scheme. The reconstructed Toolpath mesh captures the change in the Toolpath level and is an efficient pipeline for visualization, communication, and alternative purposes.

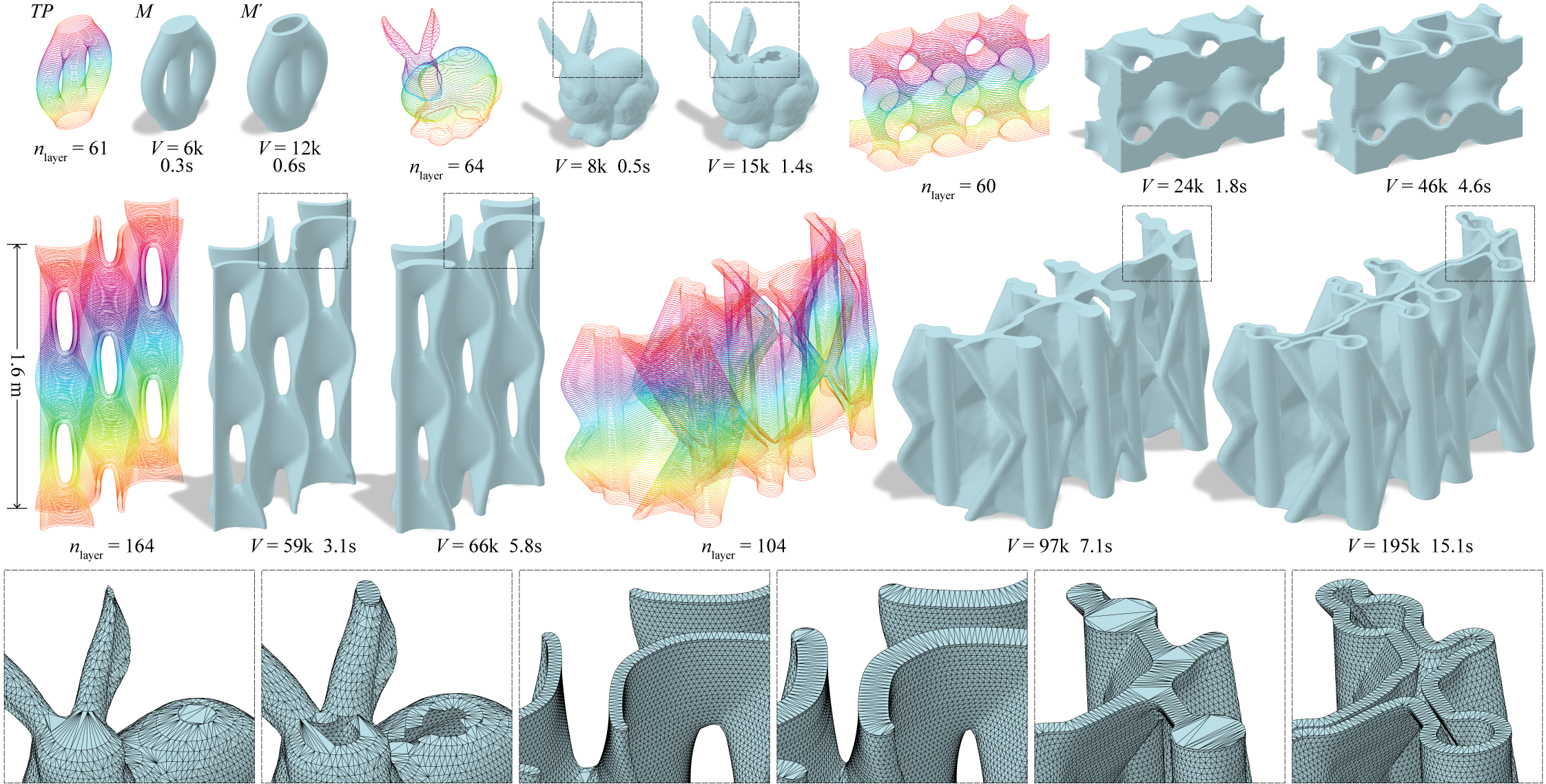

Examples of the Toolpath, the reconstructed Toolpath mesh, and the Toolpath mesh representing the extruded volume. First row: a porous column; the Stanford bunny, ©Stanford 3D Scanning Repository; a Gyroid TPMS brick. Second row: a porous panel, after Erwin Hauer (1) (2); a Diamond-TPMS-inspired component for a post-tensioned canopy structure (3) (4)

- E. Hauer, Erwin Hauer: Continua, Architectural Screens and Walls. New York, NY, USA: Princeton Architectural Press, 2004.

- Y. Zhi, H. Chai, T. Teng, and M. Akbarzadeh, “Automated toolpath design of 3D concrete printing structural components,” Additive Manufacturing, p. 104662, 2025.

- M. Akbarzadeh, H. Chai, Y. Zhi, M. E. Ororbia, T. Teng, M. Bernhard, D. (M.) Bolhassani, F. Yavartanoo, J. Tapia, K. Pajak, M. Bernard, L. Trousset, P. Kassabian, and B. Waligun, “Diamanti: 3D-printed, post-tensioned concrete canopy,” in Proc. FABRICATE 2024: Creating Resourceful Futures, 2024, pp. 292–301.

- Image adapted from: Y. Zhi, H. Chai, T. Teng, and M. Akbarzadeh, “Automated toolpath design of 3D concrete printing structural components,” Additive Manufacturing, p. 104662, 2025.

Representing the extruded volume

An important application of

Toolpath Mesh is to create a mesh that represents the extruded volume. A Toolpath can be offsetted on both sides by

Offset Toolpath to

form a "pseudo-Toolpath" whose region represented the extruded volume (see Offsetting Toolpaths). The Toolpath mesh of this "pseudo-Toolpath" is a closed, maniford mesh representing the extruded volume. It is a compact mesh for finite-element analysis (FEA). Since it is reconstructed from the Toolpath, the FEA will reflect all modified details of the Toolpath.

Toolpath mesh as the extruded volume, showing different widths of extrusion

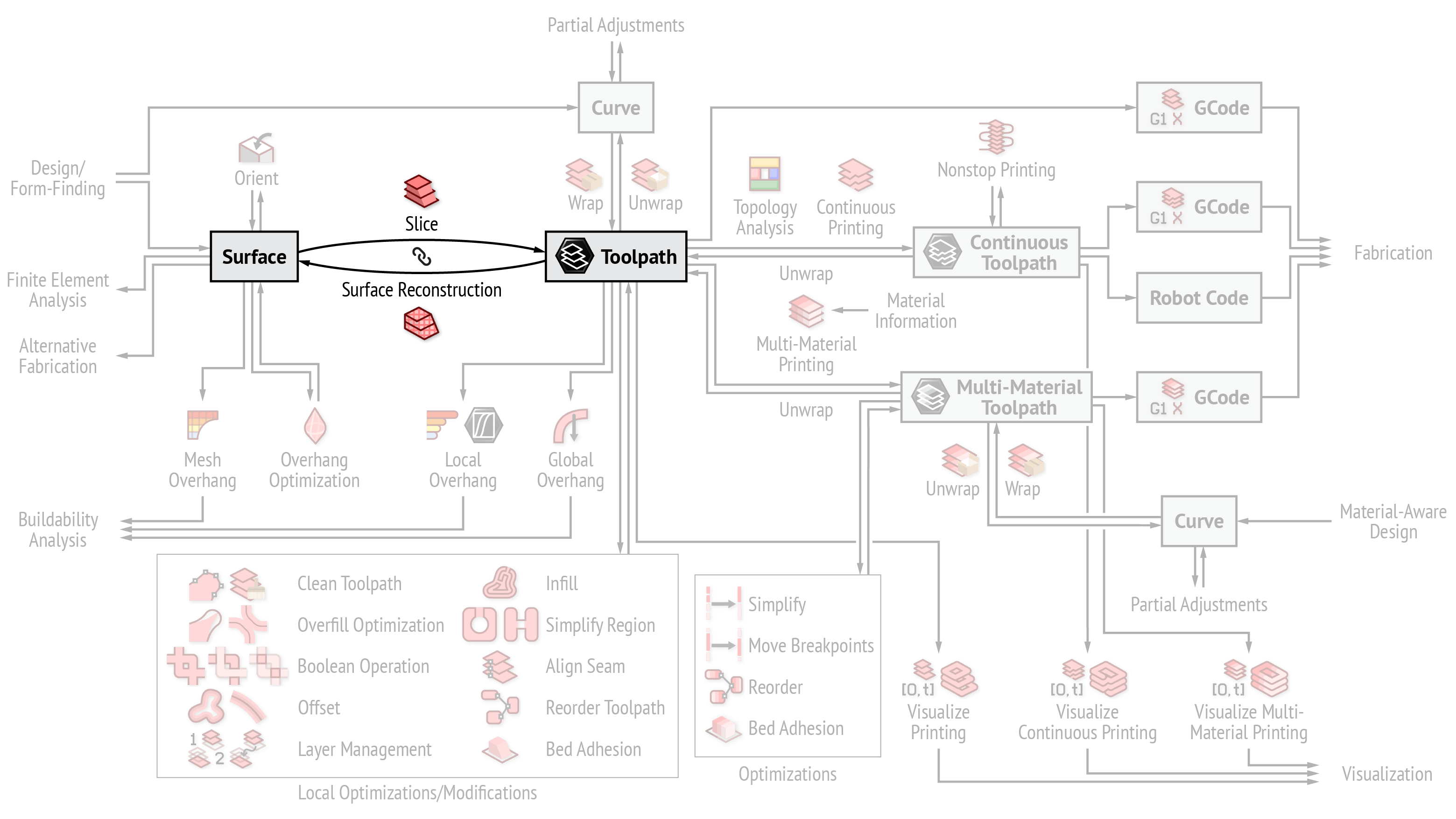

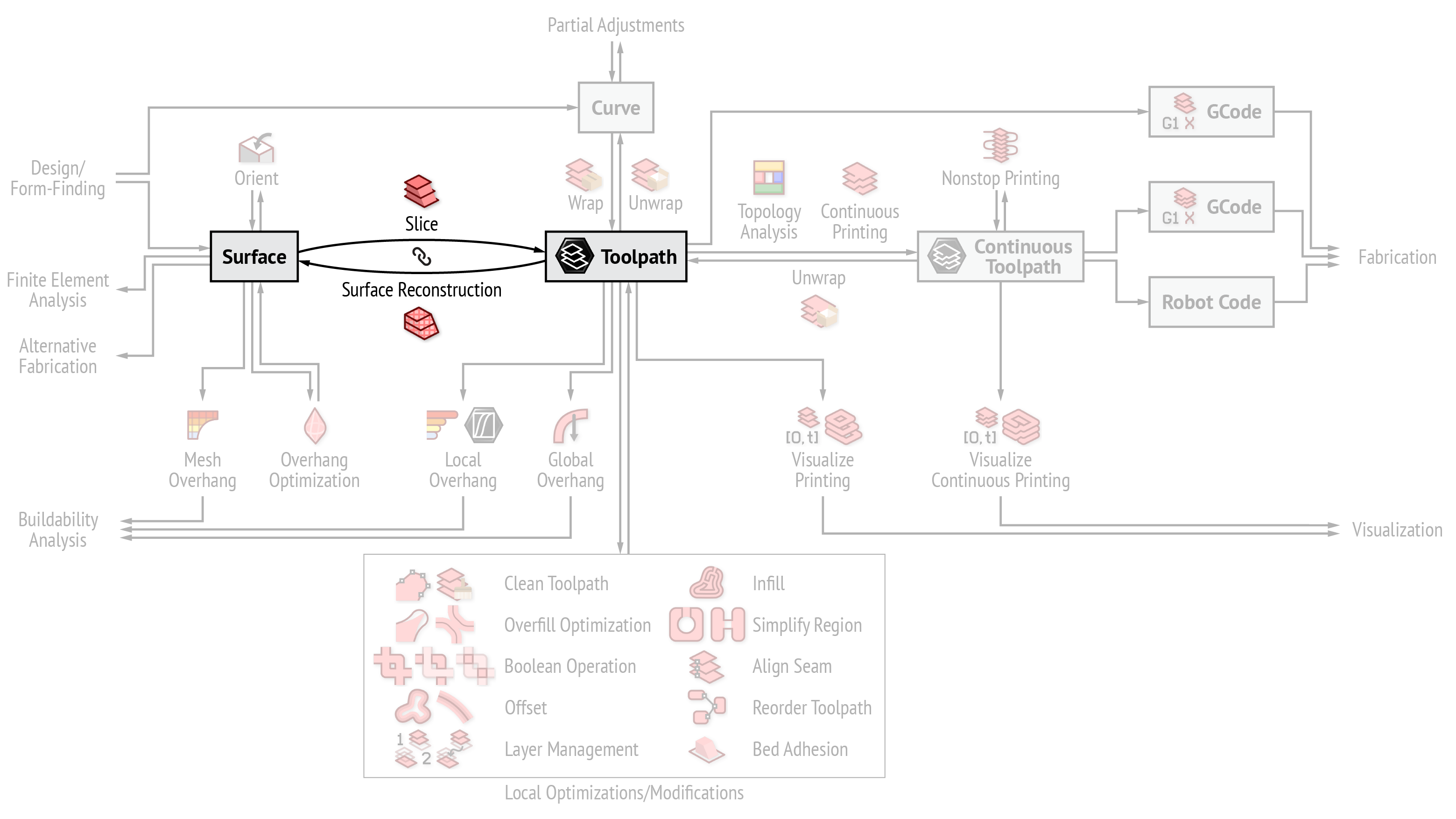

Surface-toolpath twins

The efficient and effective surface reconstruction algorithm brings about a new view of toolpath design. It is no longer a unidirectional process.

The surface and the Toolpath are now syncronized to form what we call the "surface-toolpath twins". The design-to-production process is now bidirectional: One can plug and play different form-finding results, assess and optimize their fabrication schemes in the conventional way, or leverage knowledge in fabrication design, model toolpath curves as sections, reconstruct surfaces, and merge them into form-finding and segmentation in an inverse way.

The Ovenbird framework highlighting the surface-toolpath twins

The Ovenbird framework highlighting the surface-toolpath twins (single-material only)

Below is a minimal example of utilizing the surface-toolpath twin idea to reconstruct a surface from a limited number of curves. The surface is then refined and sliced to have denser layers.

For a comprehensive introduction to the proposed bidirectional workflow, please refer to our paper Surface-Toolpath Twins of Shell Components in 3D Concrete Printing for Optimized Buildability and Surface Quality. (1)

- Y. Zhi and M. Akbarzadeh, “Surface-Toolpath Twins of Shell Components in 3D Concrete Printing for Optimized Buildability and Surface Quality,” in Proceedings of IASS 2025 symposium: The living past as a source of innovation, Mexico City, Mexico, Oct. 2025.