Gradient printing

Seam defect

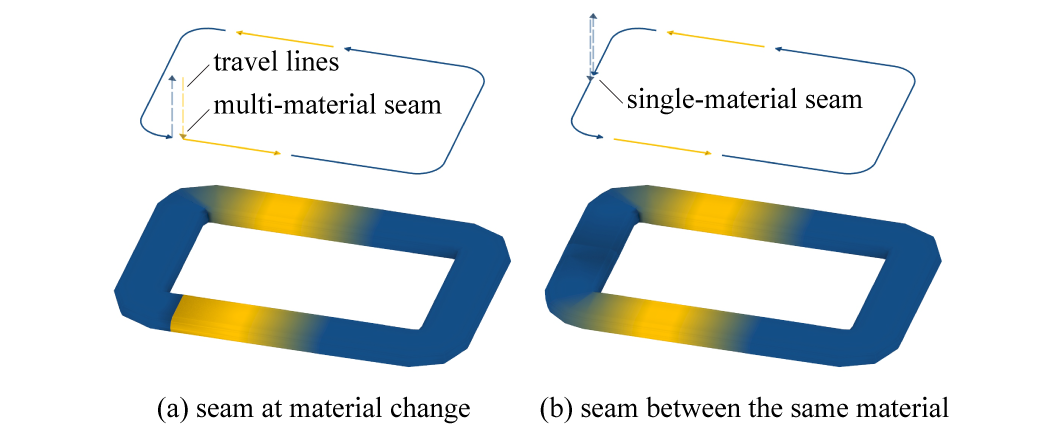

For multi-material closed curves, the original seam in a single-material

Toolpath is naturally replaced by one of the material changes in the

Multi-Material Toolpath to minimize the number of single-material segments. Consequently, the curve starts and ends with different materials, which introduces a visible multi-material seam defect without gradient transition. This defect can be replaced with gradient transition by having the seam of the multi-material curve at the middle of any of the single-material segments.

Multi-material seam defect

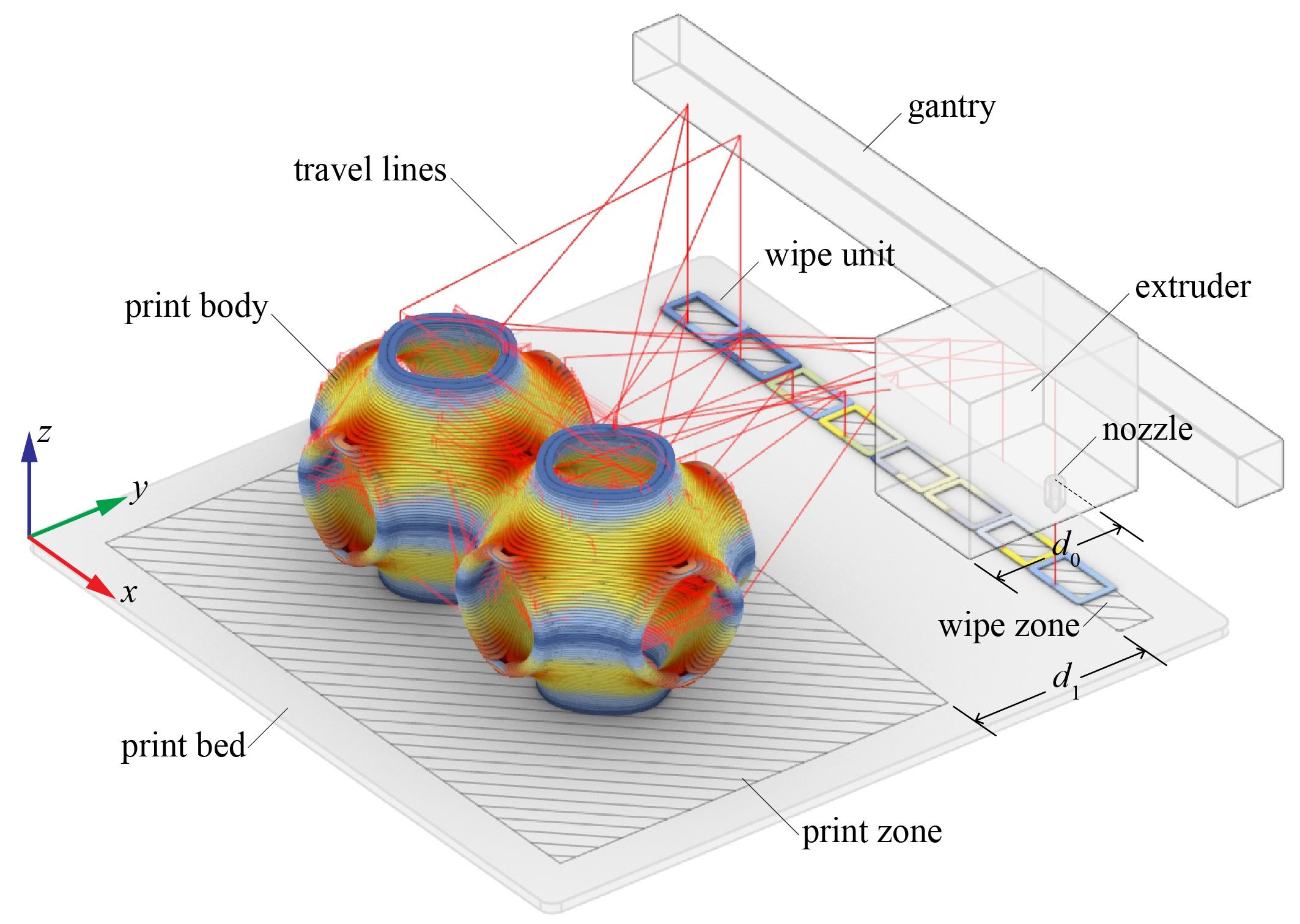

Wipe units

Now the nozzle will enter and exit with the same material, called the transit material.

When the nozzle travels between two curves of different transit materials, a wiping stop is needed. The nozzle typically extrudes somewhere off the print body to complete the material transition. For each transition, we place a rectangle curve known as a wipe unit whose length should be greater than the transitional length \(L_{2}\), preferably with a factor. To place the wipe units, a

Multi-Material Print Bed should be used.

Reorder for continuous printing

Cross-layer continuous printing of branching, porous geometry requires a slender, long nozzle, which is incompatible with multi-material filament extrusion as the mixing chamber must stay close to the outlet to prevent clogging. Sequential planning thus aims to minimize multi-material seam defects and the number of accompanying wipings.

Reorder Multi-Material Toolpath uses a greedy algorithm that replaces the seam points to reduce seam defects, reorders the multi-material curves of each layer, and generates necessary wipe units.

Print scheme of two cells of Schwartz P TPMS on a \(300 \times 300\text{ mm}\) print bed, showing the wipe units. This 90-layer print uses 8 wipe units, saving 91% of the wiping material, 11% of the total material

Example Files

9. Multi-Material Printing → (6) Reorder

9. Multi-Material Printing → (7) Comprehensive Example

Bed Adhesion

We can add

Multi-Material Bed Adhesion (skirt or brim) to a

Multi-Material Toolpath to prime the nozzle and enhance stability and adhesion. It should be added before

Reorder Multi-Material Toolpath.